Manufacturing and Supply Chain M&A Outlook

With inflation and higher interest rates continuing to ease along with greater flexibility in dealmaking, industrials are a key sector for dealmakers this year, as many seek out innovative technologies, digital assets, and supply chain resilience

The Benefits of MOM & MES and Why the Differences Matter

Mike Bradford Strategic Business Development Director at DELMIA, takes a closer look at some of the biggest differences between MES and MOM, and why these differences are critical to manufacturing success.

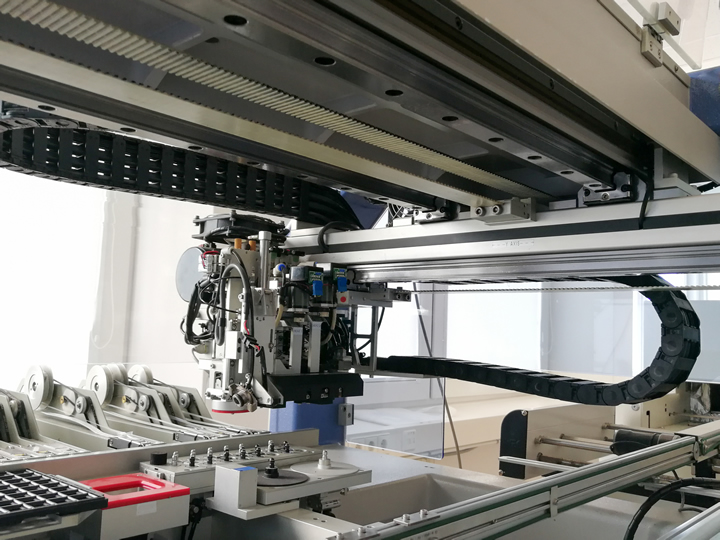

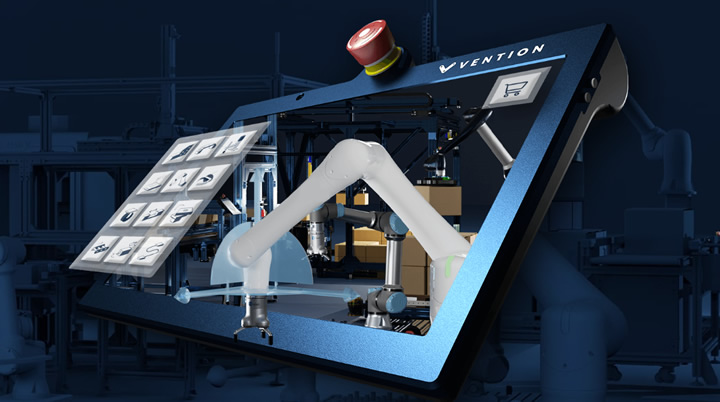

Foundations for Success In Industrial Automation: A Guide for Small to Medium Manufacturers, Part III

Once you've pinpointed what you will automate, it's time to develop a project roadmap. Here is how to best transform your preparatory efforts into an actionable plan:

Industrial AI begins: Curse or blessing?

Artificial Intelligence has emerged as a transformative force in industry. Its applications in automation and predictive analytics have reshaped traditional workflows, paving the way for more efficient across multiple sectors.

Human-Centred Digitisation: Bridging the Gap Between Technology and People in Manufacturing

Amidst this surge towards digitalization, especially on the shop floor, there exists a paradox that we at Elisa IndustrIQ find both fascinating and challenging. A human-centred digitization approach could be the solution.

Foundations for Success In Industrial Automation: A Guide for Small to Medium Manufacturers, Part II

Once the objective has been established, a team has been assembled and management has bought into the initiative, it's time to evaluate which part of your operation to automate first. While there are many factors to consider, here are a few recommendations:

Foundations for Success In Industrial Automation: A Guide for Small to Medium Manufacturers

While automation has become increasingly within reach, it can still be overwhelming for many manufacturers. Before starting their first project with the technology, manufacturers must take some essential steps to lay the foundation for success and yield long-term benefits.

Overcoming Manufacturing Challenges in 2024

The only way to meet customer demand for speed, accuracy, and quality is to digitally transform. As our industry leverages new technologies that enable better processes, talent must evolve with it. No industry can afford to stand still, and manufacturing is no different.

5 Security Risks of Rushed Digital Transformation

Undergoing a digital transformation is necessary for many manufacturing businesses, especially when they must stay competitive in challenging market conditions. However, if the responsible parties rush things, they'll increase the likelihood of several security risks.

Ultimate Customization - When Is It Justified for Enterprise Internet of Things?

To avoid choosing between the lesser of two evils, we offer to dive into cases where customization is fully justified and even more - when it's necessary for the EIoT solution to succeed.

How a Collaborative Approach is Driving Industry 5.0 Adoption in Ireland

In Ireland, unlocking the potential of Industry 5.0 is a larger group effort. Manufacturers, government bodies and academic institutions are all working together, and their efforts are proving fruitful - with projects even being help up as global examples.

Why It's Essential to Prioritize Digital Transformation for B2B Business

As business evolves, manufacturers and distributors are going digital. Today's B2B buyers want more self-service eCommerce, and B2B companies are responding.

Breaking down Walls to Build e-Factories

Thomas Burke, Global Strategic Advisor at CC-Link Partner Association (CLPA), looks at how industrial automation vendors, machine builders, and end users can futureproof robotic systems with value-adding network technologies.

6 Steps to Industrial Digital Transformation

Most digital transformation projects must be implemented quickly and efficiently to maximize returns. Projects tend to have short deadlines with expectations for immediate returns while laying the foundation for long-term results.

The Redesign of Manufacturing is Inevitable: What Does it Mean for Humans?

It's clear that the way humans have traditionally been used in manufacturing is neither good for the industry nor for these individuals. This truth has been overlooked with apprehension about what change will mean for millions of workers in the industry.

Records 1 to 15 of 42

Featured Product

T.J. Davies' Retention Knobs

Our retention knobs are manufactured above international standards or to machine builder specifications. Retention knobs are manufactured utilizing AMS-6274/AISI-8620 alloy steel drawn in the United States. Threads are single-pointed on our lathes while manufacturing all other retention knob features to ensure high concentricity. Our process ensures that our threads are balanced (lead in/lead out at 180 degrees.) Each retention knob is carburized (hardened) to 58-62HRC, and case depth is .020-.030. Core hardness 40HRC. Each retention knob is coated utilizing a hot black oxide coating to military specifications. Our retention knobs are 100% covered in black oxide to prevent rust. All retention knob surfaces (not just mating surfaces) have a precision finish of 32 RMA micro or better: ISO grade 6N. Each retention knob is magnetic particle tested and tested at 2.5 times the pulling force of the drawbar. Certifications are maintained for each step in the manufacturing process for traceability.

.jpg)

.jpg)